Description:

Process Flow: Raw Material → Rinsing →Sugaring→Shaping→ Baking→ Sorting→ Packing

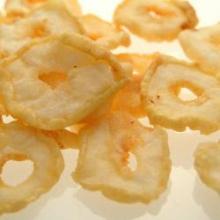

Preparation Method: Select superior crisp pears yielded by local green organic orchards as raw material, clean with clear water, enucleate and cut into sections, add White Sugar into stainless steel kettles for boiling to keep pear sections nondeformed, fish out the pear sections from sugaring liquor, put into baking plates, send into baking rooms, ventilate and dehumidify, and produce full flat, non-shrunken, noncrystalline, compact and non-coarse, golden yellow, sweet and sour, palatable and non-burnt Preserved Fruits with evenly-distributed sugar, and finally sort and package.

Health Benefits:

1. Dried pears are a good source of vitamin C, folate and dietary fiber.

2. Dried pears provide iron and potassium and contain pectin, a soluble fiber that helps control cholesterol levels and cellulose. Furthermore they contain fiber which promotes healthy bowel movement.

|

Specifications:

Moisture: 18-22%

SO2: 100ppm max; Sugar: 60-65%

Packaging: in 12.5kg carton inner with food grade poly bag; |

|

18MT/20'FCL.

Picture 1: dried pear halves with sugar

Picture 2: dried pear halves without sugar |

Tags: dried pear, dried pear halves.