|

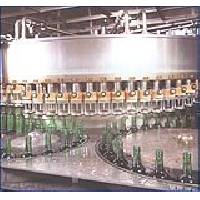

Detailed introduction to Filler and capper:

FEATURES

VERSATILE

Round bottles from small to large can be handled by the same machine. Moreover, shaped bottles such as rectangular bottles can also be handled by an attachment changeover.

EASY LEVEL ADJUSTMENT

Filling levels can be increased or decreased by adjusting the filling valves. Also the valves are drip-free, ensuring uniformity in the filling levels.

-GRAVITY FILLER [SMALL BOTTLES]

FEATURES

ACCURATE FILLING

The filling valve of which the design is based on many years of experience, provides low-foaming filling, meticulous consideration for a drip-free valve construction allows highly accurate filling to be achieved.

EASY CLEANING

The filling valve constructed from simple parts provides easy cleaning and quick dis-and reassembly.

VERSATILE

Various small bottles can be filled just by using the attachment change over.

-HIGH PRESSURE FILLER

FEATURES

FILL-TO-A-LEVEL FILLING

As this filler uses the overflow method to return liquid exceeding a predetermined filling level to a Tank outside of the machine, constant level filling can be always achieved.

SANITARY

As the product contact parts are made of materials which are suitable from the viewpoint of product properties and are carefully machined, the machine can be used for a long time without any problem.

-PISTON FILLER [GENERAL USE FILLER]

FEATURES

ACCURATE FILLING

The most critical component in this volumetric piston type filler, the cylinder, is specially designed for air to be automatically evacuated so as to achieve highly accurate filling.

SANITARY

As all driving mechanisms such as the piston cam and bottle lifter cam are installed below the bottle conveyors, filling is very sanitary.

EASILY CLEANABLE VALVE

The filling valves, which can be easily dis-and reassembled, allows easy cleaning.

EASY ADJUSTABLE FILLING VOLUME

The volumes of all cylinders can be changed at the same time by one handwheel.

-FILLER/CAPPER MONOBLOCK

FEATURES

SPACE-SAVING

As a single starwheel connects a filler to a capper, floor space is minimized. Handling problems between filler and capper are eliminated.

SANITARY

As the bottle is closed immediately after filling, sanitary operation is achieved.

MANY VARIATIONS

An optimum system can be chosen from many models of filler and capper to suit various kinds of bottle and cap, and production speeds.

-18.9L FILLER/CAPPER

FEATURES

ACCURATE FILLING

As the bottle is chosen immediately after filling Sanitary operation is achieved.

EASY CLEANING