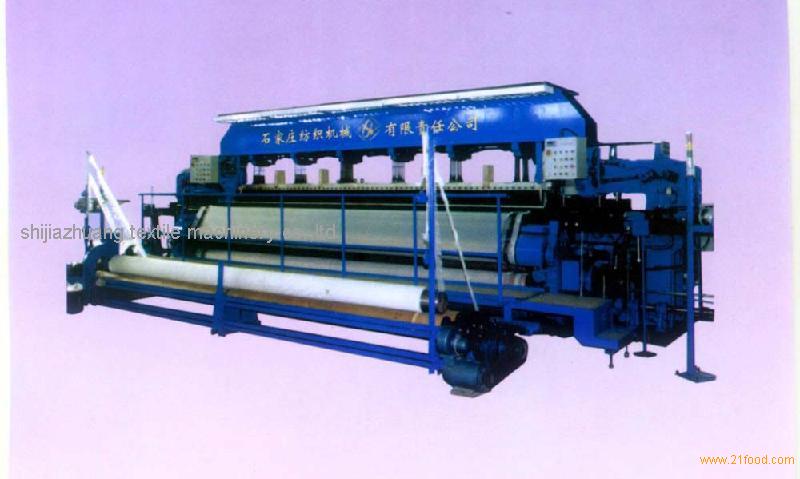

This is a wide heavy loom designed on the basis of global standard and drawing lessons from the products both at home and abroad. It is used to weave polyester single-layer and multi-layers forming fabric for papermaking, dryer fabric, and filter screen, fabric and press fabric used in other industries.

Technical Parameters:

1. Range of polyester monofilament:

0.1~1.0mm

2. Weft density:

100~1200 picks/10cm

3. Fabric width:

5.5m, 12.5m.

4. Max. loom speed:

37rpm

5. Gross power of the complete machine:

30

???

41 KW

6. Weight:

about 45

???

65T

7. Overall dimension

(mm) :

length×width×height: (11200

???

18200)×7550×2600

Main constructions:

1. Framework:

themain wallboard adopts iron box structure; the complete machine is combined with fissions.

2. Main drive:

adopting bilateral motor two-sided coaxial drive; double pneumatic clutch.

3. Weft insertion mechanism:

adopting hydraulic picking mode; automatic weft holding; pneumatic shuttle checking; six-color weft selecting device.

4. Shedding mechanism:

adopting two-sided dobby shedding; sixteen heald frames.

5. Beating-up mechanism:

adopting multi-fissions combined crank four-linkage weft beating.

6. Take-up mechanism:

adopting electronic control three-roller positive take-up.

7. Let-off mechanism:

adopting electronic control positive let-off (double warp beam, flange-separating warping).

8. Web-rolling mechanism:

adopting external superficial web rolling driven by independent torque motor.

9. Lubricating system:

The complete machine is lubricated with automatic grease lubrication and hand pump centralized oil lubrication.

10.

Control system:

With PLC computer control system, the complete machine can freely set various parameters and automatically display faults.