|

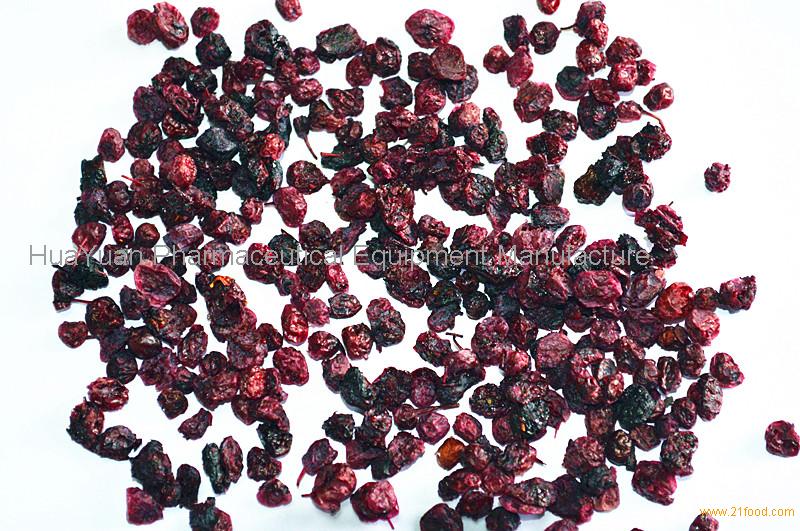

Microwave vacuum dryer for strawberry/blue berry /banana/herbs/herbs extract/fruits concentration/ fruits juice

Application:different foodstuff process

u Fruits concentration or juice drying in tray

u Fruits washing-romoving stone-slicing or dicing-preserved by sugar or salt-drain the water-Microwave drying-cooling-packaging

u Vegetables stem&leaves washing-slicing or dicing--drain the water-Microwave drying-cooling-packaging

u Herbs or vegetable roots washing-slicing or dicing-drain the water-Microwave drying-cooling-packaging

u Vegetables-washing-boiled-slicing or dicing--drain the water-Microwave drying-cooling-packaging

Compare:effect after drying by different machine

u Vacuum technology decrease the boiled point,suitable for heating sensitive production,such like high Vc,Va content production. u Widely application:banana/pineapple/papaya/apple slice,datas,strawberry,bluebeery,sea cucumber,shrimp,

vegetables,leaves,roots,herbs,nuts....,fruits concentration,herbs concentration....

u finished foodstuff has crispy and delicious flavor, grain puffed full, natural color, good appearance, and has insecticidal sterilization,good rehydration.

u Temperature adjustable range:30- 80 ℃

u high energy conversion efficiency, fast heating:Microwave oven itself does not heat, but the microwave energy to penetrate the material, so that the friction between polar molecules within the material generated internal heat. Instantly vaporized liquid is heated so that the processing of material internal expansion force booster expansion ua rely on gas to make structural components of the polymer material variability, and to become more porous substance with structural features network organization, stereotypes.

u bactericidal effect:microwave baking at the same time has sterilizing function in the lower temperature for a

u short time. The sterilization temperature is generally about 80 ℃ , the treatment time is 3-5 minutes, and can maintain the Normal nutrients.

u easy to operate. Microwave power and conveyor speed can be stepless adjustment.

u Improve the production environment. Microwave equipment without heat radiation, no dust, no noise, no

u pollution, easy to implement testing standards of food hygiene.

u puffing effect is obvious. Rapid heating effect of microwaves, so that the material inside the rapid

u vaporization of water molecules to achieve the purpose of puffing.

u less loss of nutrients for low-temperature sterilization.can maintain the maximum of its nutrients. Retention

u of vitamin C is 46-50% of conventional heat treatment of fruits and vegetables, microwave it can reach 60-90; vitamin A to maintain conventional heat treatment was 58%, while the microwave treatment is 84%, and does not affect the original flavor, is a fruit and vegetable food processing, get a good means of green food.

Our company is located in Beijing and is specialized in the R&D and manufacture of traditional Chinese pill making equipment series, microwave extracting equipment series, microwave drying & sterilizing machine series, traditional Chinese medicine packaging machine series, and medical sterilizing cabinet series. Our enterprise now possesses 8 national patent licenses with independent intellectual property, all developed independently, and over 20 patents. We have exist types of CNC equipment, machining centers and other modern proceeding equipment of more than 300 units, with installation and debugging capabilities from the stand-alone processing production to the complete sets of equipment. We can recommend the best equipment and program according to customers' different conditions.

With an experienced and professional team, we have exported our products to many countries and regions all over the world, especially France, Australia, Japan, Russia, Southeast Asia, and other countries and regions. Our products enjoy a good reputation among our customers. We welcome customers, business associations and frie