|

|

Model

|

Diamter (mm)

|

High (mm)

|

Area of dry (

m 2

)

|

Power (kw)

|

|

1200/4

|

1850

|

2608

|

3.3

|

1.1

|

|

1200/6

|

3028

|

4.9

|

||

|

1200/8

|

3448

|

6.6

|

1.5

|

|

|

1200/10

|

3868

|

8.2

|

||

|

1200/12

|

4288

|

9.9

|

||

|

1500/6

|

2100

|

3022

|

8

|

2.2

|

|

1500/8

|

3442

|

10.7

|

||

|

1500/10

|

3862

|

13.4

|

||

|

1500/12

|

4282

|

16.1

|

3

|

|

|

1500/14

|

4702

|

18.8

|

||

|

1500/16

|

5122

|

21.5

|

||

|

Jun-00

|

2900

|

3262

|

18.5

|

3

|

|

Aug-00

|

3682

|

24.6

|

||

|

Oct-00

|

4102

|

30.8

|

||

|

Dec-00

|

4522

|

36.9

|

4

|

|

|

2200/14

|

4942

|

43.1

|

||

|

2200/16

|

5362

|

49.3

|

5.5

|

|

Model

|

Diamter (mm)

|

High (mm)

|

Area of dry 2 (m )

|

Power (kw)

|

|

2200/18

|

2900 3800 |

6202

|

61.6

|

7.5

|

|

2200/20

|

6622

|

67.7

|

||

|

2200/22

|

7042

|

73.9

|

11

|

|

|

2200/24

|

7462

|

80

|

||

|

2200/26

|

4050

|

48

|

||

|

Aug-00

|

5782

|

4650

|

60

|

13

|

|

Oct-00

|

5250

|

72

|

||

|

Dec-00

|

5850

|

84

|

||

|

3000/14

|

6450

|

96

|

||

|

3000/16

|

7050

|

108

|

||

|

3000/18

|

7650

|

120

|

15

|

|

|

3000/20

|

8250

|

132

|

||

|

3000/22

|

8850

|

144

|

||

|

3000/24

|

9450

|

156

|

||

|

3000/26

|

10050

|

168

|

|

|

|

3000/28

|

10650

|

180

|

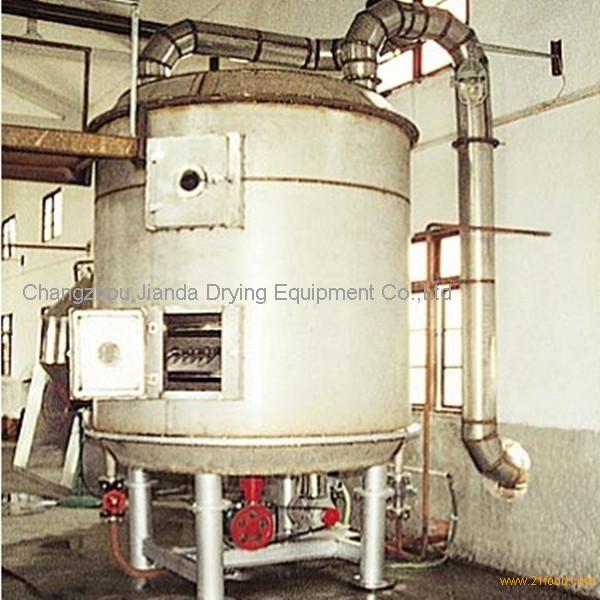

Changzhou Jianda Drying Equipment Co., Ltd was founded in 1980; it is the first China and USA joint venture company in drying industry and a well-known brand name that is specialized in drying equipments. Our company is located in Dongqin Industry Development area, suburb of Changzhou, the center of Yangtze River delta. Transportations are very convenient. We cover more than 30 thousand square meters land and hold 50 million RMB fixed asset. Surrounded environment is excellent.

Through over twenty years' sound developments, Jianda has been ranked as one of the top producers in drying equipment industry in China, and developed 36 kinds of main products and more than 260 special models with high quality. Those products are widely applied in chemistry, foodstuff, pharmaceutical, electronic industry, etc. We can manufacture more than 1000 sets of different equipments for drying, granulating, mixing and crushing. Since 1993, Changzhou Jianda Drying Equipment Co., Ltd has introduced the most advanced technique and management experience from foreign partner, Tony International Trading Inc. Since then, our technology and management have achieved the developed international standards. Jianda has been designing meticulously and innovating continually. Many products are unique and reach international advanced level.

Depending on great strength, high effective organization, outstanding talents, superior technique and excellent reliable services, Changzhou Jianda Drying Equipment Co., Ltd has a unique position in this highly competitive industry.

Under the lead of members of Chemical Industry and Engineering Society of China in drying industry and professorial senior engineers, the company has trained a strong technical team formed by senior engineers, engineers and assistant engineers. The team is responsible for technical design, processing design, fabricating inspection and final quality control. Each worker and technician has got training certificates. We also set quality control manager in each process from raw material in storage to final equipment delivery.

more

|

|

|

|

|

|

|

|

|

|

|

|