|

Automatic Rice Flour Instant Noodle Making Machine

1 Industrial plant, standardize production

2 Continuous process,save cost

SNTNRS24 Automatic Rice Flour Instant Noodle Making Machine

Introduction

SNT Machinery specializes in extruding noodles production lines more than 20 years with good reputation and service.Our production lines are founded almost in every province in China. We also export the extrusion machines to U.S., South Korea, North Korea, India, Sri Lanka,Mauritius, etc.

This auotmatic rice flour instant noodle making machine is highly controlled from rice flour mixing, Rice Noodle forming, aging,steaming, drying and packaging. The whole process is continuous and standardize.

Spec.

| Model |

SNTNRS24 |

| Daily output |

240000pcs/24hrs (70g/pc) |

| Hourly output |

10000pcs/hr |

| Dimension |

80m*6.5m*3.5m |

| Compressed air |

1.2 m3/min |

| Steam |

1050kg/h |

| Water consumption |

7 tons for flour mixing, 20 tons for circulating |

| Power |

285kw |

| Operators |

15 persons |

Rice instant noodle

Automatic production line

Miniature show at the fair

Technique support & good after sale service

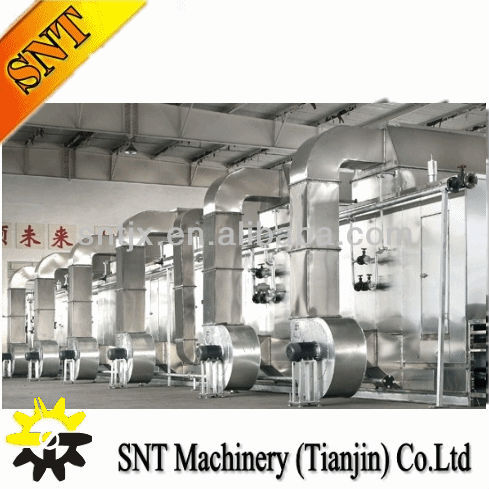

Main devices

1, flour mixer

2, ripening feeder

3, lifting conveyor

4, flour rationing feeder

5, extruding forming machine

6, rationing Cutting Machine

7, noodles combining conveyor

8, noodles adjusting machine

9, noodles distributing machine

10, aging machine

11, steaming machine

12, drying machine

13, Cooling Machine

14, connection conveyor

15, inspection conveyor

16, production conveyor

Main feature

| 1 Automatic production process The whole production line is highly controlled automatically from flour mix ing to the final products, less manual operation. The operators only need to observe, monitor and adjust the equipment. |

| 2 C ontin u ous aging process The automatic aging tunnel is adopted multi-level cycling design, go-and -back movement to shorten the machine length. To promote the aging effect and shorten the aging time, heat and humidity kept in side. |

| 3 Excellent drying effect To meet the drying curve demands and reach the excellent drying effect, we adopt the up-and- down multiple-level design and divide the space of the dryer . Humidity and temperature is strictly controlled in each section. |

| 4 Precise weight control The weight of each piece noodle cake is stable, precisely controlled by the central system composed of frequency. |

| 5 Use kinds of flours as raw material wet milling rice flour, dry milling rice flour, starch flours etc. |

| 6 M ulti - purpose machine P rocess different kinds of flours, products as instant rice noodle, starch vermicelli, wheat flour non-fried noodle, corn flour noodle, buckwheat noodles, oats noodle , barely noodle etc . |

Service System

| 1,supply solutions for the buyers’ special demands |

| 2,design plant layout and help complete the installation |

| 3,provide technical support both at setup and maintain |

| 4,cultivate the operators |

Models

| Model |

Daily output (70g/pc) |

Dimension (LxWxH)m |

Compressed air (m3/min) |

Steam Kg/h |

Power Kw |

Operators |

| NRS 4 |

40,000pcs |

60x3.2x3.5 |

0.6 |

330 |

86 |

7 |

| NRS 8 |

80,000pcs |

80x3.2x3.5 |

0.6 |

500 |

108 |

7 |

| NRS16 |

160,000pcs |

80x4.6x3.5 |

0.9 |

820 |

195 |

10 |

| NRS24 |

240,000pcs |

80x6.5x3.5 |

1.2 |

1050 |

285 |

15 |

| NRS36 |

360,000pcs |

110x6.5x3.5 |

1.5 |

1400 |

450 |

15 |

Automatic Instant Rice Noodle Making Machine

Welcome to SNT

Contact Information

| Condition: |

New

|

Type: |

Noodle

|

Production Capacity: |

16.8tons/24hours

|

| Place of Origin: |

Tianjin China (Mainland)

|

Brand Name: |

SNT

|

Model Number: |

SNTNRS24

|

| Voltage: |

380V

|

Power(W): |

285kw

|

Dimension(L*W*H): |

80m*6.5m*3.5m

|

| Warranty: |

12 months

|

After-sales Service Provided: |

Engineers available to service machinery overseas

|

Daily output: |

240000 pcs/24hrs ( 70g/piece)

|

| Marerial: |

stainless steel

|

Compressed air: |

1.2 m3/min

|

Steam: |

1050 kg/h

|

| Water consumption: |

7 tons for flour mixing, 20 tons for circulating

|

Operators: |

15+

|

Technology: |

twice extruding

|

| Production Material: |

wet-milling or dry-milling rice flour

|

Spare parts: |

for 1 year's operation

|

|

|

|

|

|

|

|

|

|

|

|

|