|

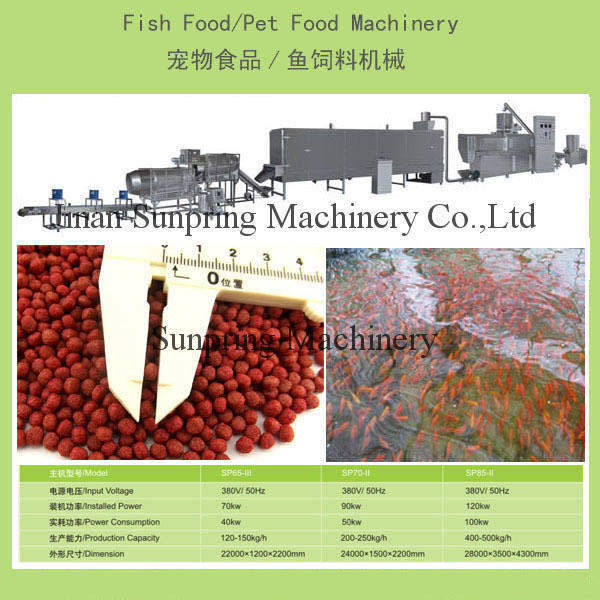

Fish feed Machine

1. Description:

Fish feed machine can be used to producing floating fish feed and sinking fish feed. The floating fish feed pellet machine can make kinds of feed, such as food fish, catfish, shrimps, crab, etc. the fish pellet made by the machine can float on water more than 24 hours. Gelatinization degree can reach 90%, enhance the output of fodders, it is suitable for making floating feed, pet food, fish fodder. The diameter of particle is Φ0.6-16mm. Promising fodder output evenly and continuously.

2. Raw materials: adopts Corn flour, soya meal, fish meal etc. as raw materials

3. Products: This line can be used to produce fish pellets, the pellets size can be from 1.0mm to 9.0mm by adjusting the moulds from extruder; meanwhile it can produce dog food, cat food.

4. Capacity: 150kg/h, 240kg/h, 500kg/h, 1ton/h, 2ton/h

5. Flow chart: Mixing system---Extrusion system---- -Drying system----Flavoring system---Packing system

6. Voltage in

7. Machines Materials:All the machines are made by stainless steel

8. Technical Parameters

Model Installed power Real power Output Dimension

SP65 81.5kw 53kw 100-150kg/h 21000x1200x2200mm

SP70 115kw 76kw 200-240kg/h 23000x1500x2200mm

SP85 181kw 117kw 400-500kg/h 28000x3500x4300mm

SP90 135kw 100kw 1000kg/h 30000x3500x4300mm

SP115 165kw 115kw 2000kg/h 30000x3500x4300mm

9. Package: Outside package: Standard export wooden case. Inner package: stretch film

10. We Provide Satisfied Service & Turnkey Solution

a. We can keep product design in the same level with internationally advanced technology consistently.

b. We have high diathesis staff and excellent processing equipment, and quality control runs through the whole production process from parts stock to the beginning of production.

c. We can guarantee customers superior quality machines up to design requirements and perfect working state.

d. Our technicians can also provide all kinds of relevant technology to make the food production clean, healthy and safe.

e. We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

f. We provide 1 year complete Guarantee and life-time maintenance service

If you have any needs or enquiries, please feel free to contact me.

11. FAQ

1.What's your payment terms?

Our payment terms is 40% T/T as down payment, 60% by irrevocable L/C at sight or T/T before delivering

2. What's your Guarantee?

We provide 1 year complete Guarantee and life-time maintenance service

3. How about the installation?

We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

If you have any needs or enquiries, please feel free to contact us!

Sunpring is a leading manufacturer of high quality Twin Screw Extruders for the food industries. We have many years' experience of working with our customers providing specialist designs and practical solutions for a wide range of process needs. The latest Computer Aided Design (CAD) technology is used by our experienced design team.

We can keep product design in the same level with internationally advanced technology consistently. Moreover, we have high diathesis staff and excellent processing equipment, and quality control runs through the whole production process from parts stock to the beginning of production. we can guarantee customers superior quality machines up to design requirements and perfect working state. Our technicians can also provide all kinds of relevant technology to make the food production clean, healthy and safe.

Sunpring Company engages in the technical research of extrusion foodstuff, in order to let our clients have superior foodstuffs to sell in the market. We can improve client's equipment and provide related training on new advanced technique. We can also make special designs for special products and materials according to clients' special requirements.

At present, Our Company locks in 70% market share in

Sunpring has been supplying the most efficient equipment available to snack manufactures around the world. A comprehensive range from mixers to extruders, ovens machines offers core filler and easy to operate designs which lead the industry. Each process line is specially selected to suit the individual product characteristics and requirements of each customer.

Twin Screw Extrusion provides the starting point for a wide range of higher quality sweet and savory snacks. Sunpring is a leader in twin screw technology but has in addition focused on the downstream dies, cutting and packing devices which are the key to efficient manufacture of differentiated products.

|

|

|

|

|

|

|

|

|

|

|

|