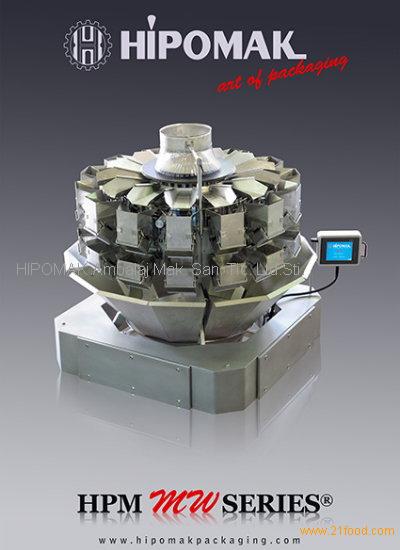

The HIPOMAK MCW series is one of the most advanced computerized weighers to work in line with high speed automatic packaging equipment such as vertical FFS machines, baggers, etc.

The MCW series has a stepping motor system to control door openings, which can be custom set for the desired speed and batch volume. Products are fed by a central vibrator through linear vibrating feeders into intermediate pans and then discharged on demand into weighing pans. Each pan contains a certain percentage of the total target weight. The machine setting can be simply programmed and memorized to adjust for products of varying consistencies such as free-flowing and sticky products or frozen foods.

PRINCIPAL FEATURES

Improved Functionality

• Completely microprocessor controlled for easy setup and operation

• Superior accuracy

• High-speed operation

• Color touch screen

• Multiple user languages

• Statistical data

• Sturdy high quality construction

• Easy change over from one product to another

• No under weights

• Self-diagnostic

• Interfaces with F.F.S., baggers, etc.

• Quick access to all parts for cleaning and proper maintenance

• All parts in contact with products are easily dismantled for cleaning

Available Options:

• Size versions : 10, 14, 16, 16/32 weighing heads + 10 head miniature weigher.

• Buckets volume : 1.6, 2.5 and 5 liters.

• Contact parts finish : Smooth stainless steel, embossed stainless steel, Teflon® coating, and mesh.

• Body finish : Painted mild steel or completely stainless steel.

• Outputs : Single, double and quad.

• Top cone type : Vibrating, rotating, rotating for salads, powders.

• Input level control : Volume or weight.

• IP level : IP54 or IP65.

MODEL

MCW-10 MCW-14

Number of weight channels 10 14

Weight range 1000 Gr 1000Gr

Weighing accuracy 0.8Gr 0.5Gr

Weighing speed 65 p/min 110p/m

Total volume to be discharged 4 liter 240 cu/in 4 liter 240 cu/in

Power supply 220 V 50 Hz 1.5 KW 220 V 50 Hz 2 KW