|

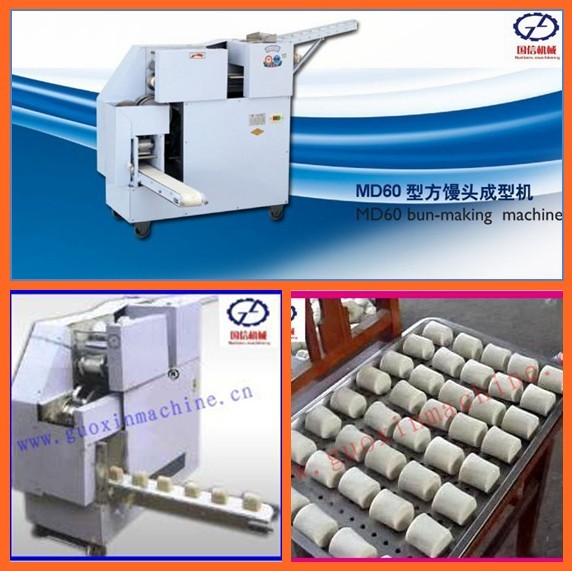

MD60 bun-making Machine, this product uses a patented technology to produce, only one person can cast surface. Automatically fol

The functional Description of MD60 bunmaking machine

1. MD60Bun-making maching Sent to face pressure to further strengthen the gluten density, bread and toughness, using secondary stirring up into the propeller instantly promote bread uniform size.

2 . MD60Bun-making maching Send three sections using surface pituitary design, easy to install, easy to disassemble, clean the internal aspects of the remaining dough.

3. MD60Bun-making maching Automatic bread machine equipment overall compact, small size, light weight, low noise, somewhat clean.

4. MD60Bun-making maching After kneading machine kneading dough the pressure after the aircraft into the desired width by surface dustpan order microemulsion pressure roller, Conveyor belt after rubbing pressure by automatically bending, forming and cutting through the second conveyor order sent.

The arguement of MD60 Bun-making Machine Bread Specifications: 5,6,7,8,9 tall / 500 g dry flour

Motor power: 1.5kw efficiency :40-480kg / h

Dimensions: 1040 * 500 * 1050mm

Weight: 330KG

Rated voltage: 380V Frequency: 50HZ

Waterproof Rating: IPX1 Motor: YL90S-4

Scope: cake room / bakery / Western shop / Candian / food plant equipment and so on

When you use MD60Bun-making maching first check the product specifications are correct, if the machine everything is normal .

1. MD60Bun-making maching Then check the "pressure roller adjustment screw" compression dough meets the requirements (by thin to thick sequence of adjustments, metering great. Small can fine tune "the pressure roller adjustment screw")

2 MD60Bun-making maching flattened dough into the fold surface bending rolls are to be naturally fall, do not hand squeeze

Pressure, which will cause measurement errors and blocking surface phenomenon.

3 MD60Bun-making maching wins to keep the knife clean after winning the sticky surface parking process may be appropriate to sprinkle a little

Flour put sticky. Each filling hole and transmission parts may be appropriate to inject lubricant.

4 MD60Bun-making maching Loosen the lower bracket fastening screw conveyor, flat adjustment to the normal working state. (Note: After starting the machine is forbidden to hand goods or other foreign objects into the roll forming roll In order to avoid danger. )

MD60 Bun-making Machine T rouble shooting and dismantlin

| Symptom |

Analysis |

Remedy |

| Not normally cut noodles |

Dougthickness 1. Superscalar 2 block panels and extruded side wheel position changes. |

1 Adjust the pressure roller adjustment screw 2 wheel position adjustment crowded plane |

| Measurement exceeded bread

|

The thickness of the dough does not meet standards

|

Adjust the pressure roller adjustment screw

|

| Cut bread ever |

Cutter dislocation, moving top Sisong |

Adjust cutter, wire tight jacking |

| Type: |

Wheat Germ

|

Made From: |

Wheat

|

Certification: |

ISO

|

| Additives: |

Flour and water

|

Processing Type: |

Pressing Cutting and Deliver

|

Weight (kg): |

330 kg

|

| Shelf Life: |

one year

|

Place of Origin: |

China (Mainland)

|

Brand Name: |

Condor

|

| Model Number: |

MD60

|

Packaging: |

Carton

|

Machine: |

Bread

|

| Machinery: |

Food Processing

|