|

| machine Model

|

SPM – 1000 l

|

| Sealing Style

|

4 Side Seal

|

| Speed

|

70 Strokes / min.

(Depending on product quality and behaviour , filling level and pack layout)

|

| No. of Tracks

|

Up to 12 Tracks

|

| Laminate specification

|

Width - 1000 mm Max.

Max. Reel Dia - 450 mm

Reel Core Dia – 76 mm

|

| Packing material

|

Heat seal Metalised Poly or Polyester Poly

|

| Format Area

|

Draw off length – 200 mm Max.

Format Width – 300 mm Max.

|

| Product to be packed

|

Shampoo

|

| Filling capacity

|

3 ml to 200 ml

|

| Sealing drives

|

Mechanical –

|

| Perforation and cutting

|

Pneumatic.

|

| Laminate roll unwind

|

Motor driven – Bonfoglioli Geared motor.

|

| Laminate Draw Off system

|

PLC based Servo driven – Allen Bradely make.

|

| Laminate tracking system

|

web aligner system – DCS type.

|

| Main control panel

|

Air cooled panel – BCH make.

|

| Electrical Spec.

|

Main Motor – 2.2 Kw, 3 F , 415 V

Connected load – 14 Kw.

Consumption – 11 Kw.

PLC controlled Operations

RTD Module

|

| Layout Dimensions

|

Length è 3200 mm

Width è 2600 mm

Height è 2100 mm

|

| Machine Weight

|

Net Weight è 3500 kgs.

Gross weight è 4000 kgs.

|

| Compressed Air

|

Operating Pressure – 6 Bar.

Consumption – 3 CFM.

|

| Machine Efficiency

|

95 %

|

| Scrap rate

|

Less than 3%

|

| Machine color

|

Mulshell Grey – powder coated.

|

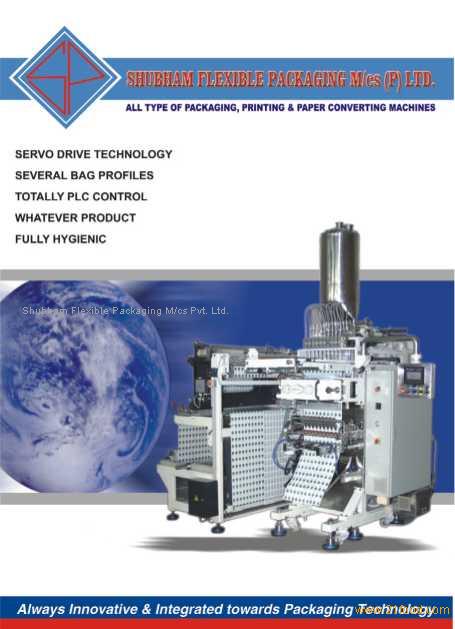

We, “Shubham Flexible Packaging Machines Pvt. Ltd” would like to take this opportunity to introduce ourselves as an innovator and leader in the field of Flexible Packaging Machines in INDIA.

Machines being manufactured by us are: Automatic Multi Track Form, Fill & Seal (FFS) Machine up to 12 Tracks for laminates. Automatic Lined Carton Packing Machine (CEKA Pack) for packing of Liquid & Powder. Automatic Horizontal Form Fill & Seal Machine with / without spout. Automatic Collar Type Fo

“Shubham” is young, enthusiastic, dynamic and creative organization with a vision of serving every customer by meeting their packaging requirement with latest and best technology.

We are serving about 15 countries all over the world including our customers like P&G, Unilever, L’Oreal, Nestle, etc. meeting their stringent requirement of quality and precision required by International Standards through our Research & Development Department.

more

|

|

|

|

|

|

|

|

|

|

|

|