|

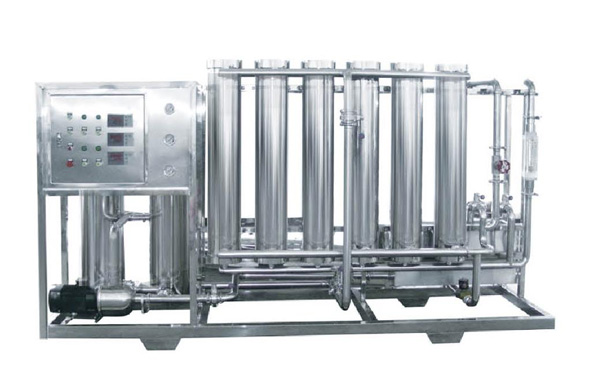

UF Water Treatment plant

1.pore size range from 0.1 to 0.005

2.Doubled pressure tolerance

3.better biofouling resistance

1. UF water treatment plant Overview

Ultra filtration is the use of porous Materials interception capabilities, ways to physically remove the water trapped impurity particles of a certain size. In pressure-driven, the solution of water, organic low molecular weight, small size inorganic ions such substances can reach through the fiber microporous membrane wall the other side of the cell solution, colloid, particulate, organic molecules and other large size substances which can not be trapped by the fiber wall, so as to achieve a solution of different components screening purposes. This process is normal operation, no phase change, does not produce secondary pollution. No phase transformation during ultrafiltration, room temperature operation, the separation of heat-sensitive material is particularly suitable, and has good acid and oxidation temperature can be below 60 °C, PH 2-11 under conditions of long-term continuous use, membrane clogging, the entire machine operation is extremely convenient.

2. UF water treatment plant Application

1) pure water and ultra pure water system preparation equipment;

2) food industry, beverage industry, dairy industry, biology, medicine;

3) industrial separation, concentration and purification;

4) industrial wastewater, electrophoretic paint, electroplating oily wastewater treatment, wastewater, industrial waste, recycling, and environmental engineering.

3. UF water treatment plant Process

General process is:

Raw water - pressurized raw water pump - multi-media Filter - activated carbon filter - water softener - precision filter - a reverse osmosis equipment - intermediate tanks - intermediate pump - ion exchange - Purification water - pure water pump - UV disinfection - Micro hole filter - water point (Chinese Pharmacopoeia 2000 edition traditional craft)

Raw water - pressurized raw water pump - multi-media filter - activated carbon filter - water softener - precision filter - the first stage RO-PH adjustment - Middle water - second stage reverse osmosis (RO membrane surface with positive charge) - purification water - pure water pump - UV disinfection - microporous filter - pasteurization - water point (Chinese Pharmacopoeia 2005 edition of the popular craft)

Raw water - pressurized raw water pump - multi-media filter - activated carbon filter - water softener - precision filter - a reverse osmosis machine - degassing membrane - Middle water - intermediate pump-EDI system - Purification water - pure water pump - UV disinfection device - microporous filter - pasteurization - water point (Chinese Pharmacopoeia 2005 edition of new technology)

Raw water - pressurized raw water pump - multi-media filter - activated carbon filter - water softener - precision filter - the first stage RO-PH adjustment - Middle water - second stage reverse osmosis (RO membrane surface with positive charge) - RO-RO tank pump-TOC resolver-EDI system - purification water - pure water pump - UV disinfection - microporous filter - pasteurization - water point (Chinese Pharmacopoeia water for injection, the European Union and the United States Pharmacopeia recommended process) [1]

Dope - tanks - pressure pump - precision filter - hollow ultrafiltration equipment - tank - the backwash water tank - backwash pump.

4. UF water treatment plant Configuration

| MODEL | MEMBRANE ID/OD | MEMBRANE AREA |

| CET-1030-B | 1.0/1.5mm (0.039/0.059') | 23 m2 ( 247.5 ft2 ) |

| CET-1060-B | 1.0/1.5mm (0.039/0.059') | 50 m2 ( 538.1 ft2 ) |

| CET-1080-B | 1.0/1.5mm (0.039/0.059') | 68 m2 ( 731.9 ft2 ) |

| CET-1030-C | 1.2/1.8mm (0.047/0.071') | 19 m2 ( 204.5 ft2 ) |

| CET-1060-C | 1.2/1.8mm (0.047/0.071') | 40 m2 ( 430.5 ft2 ) |

| CET-1080-C | 1.2/1.8mm (0.047/0.071') | 55 m2 ( 592.0 ft2 ) |

| CET-1030-D | 1.5/2.2mm (0.059/0.087') | 13 m2 ( 139.9 ft2 ) |

| CET-1060-D | 1.5/2.2mm (0.059/0.087') | 29 m2 ( 312.1 ft2 ) |

| CET-1080-D | 1.5/2.2mm (0.059/0.087') | 40 m2 ( 430.5 ft2 ) |

APPLICATION DATA

| Typical Filtrate Flux | 50~130L/m2•h ( 100~200 GFD) |

| Maximum Applied Feed Pressure | 0.5MPa ( 73psi ) |

| Maximum TMP | 0.2MPa ( 30psi ) |

| CIP Chlorine Concentrate | 100~200 ppm |

| Instantaneous H2O2 Tolerance | 200 ppm |

| Maximum Feed Turbidity | 100 NTU |

| Operating Temperature | 5~45°c ( 41~113°F ) |

| Operating PH Range | 1~13 |

| Operation Mode | Dead-end or Crossflow |

TYPICAL PROCESS CONDITIONS

| Backwash Flux | 180~240L/m2•h ( 100~200 GFD) |

| Backwash Duration | 30~60 seconds |

| Backwash Frequency | 15~120 minutes |

| CEB Frequency | 0~4 times per day |

| CEB Duration | 1~10 minutes |

| Cleaning Chemicals | NaClO or H2O2 ,NaOH ,HCl ,Citric Acid or Oxalic Acid |

| Place of Origin: |

Guangdong China (Mainland)

|

Brand Name: |

Konche

|

Model Number: |

KC-UF

|

| storage temperature: |

-20C~45C

|

Features: |

better support and physical characteristics .

|

Material: |

304or 316L stainless steel

|

| filtration media: |

hollow fibers UF membrane

|

Medium Material: |

pp

|

Type: |

UF filter

|

| Ceritificate: |

ISO

|

membrane material: |

high molecular material by special technology

|

Function: |

Water Filter

|

| UF membrane: |

asymmetric semi-permeable membrane

|

|

|

|

|

|

|

|

|

|

|

|

|