|

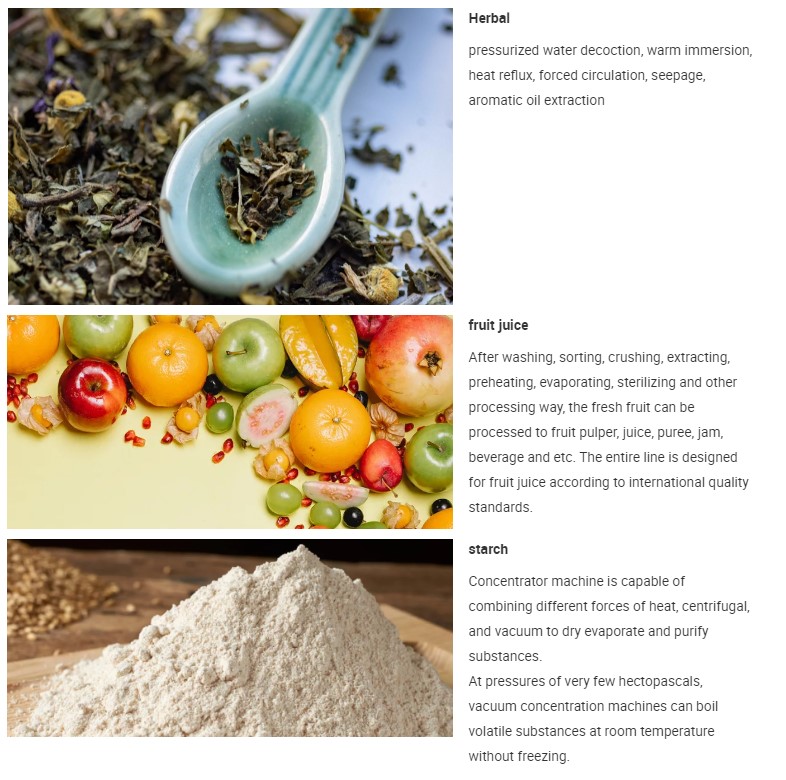

Concentrate Machine Range of Application:

Double effect concentrator is suitable for low temperature vacuum concentration of heat sensitive materlals such as traditional Chinese medicine, western medicine, glucose, wine making, starch, oral liquld, chemical industry, food, monosodium glutamate, dairy products.

|

Specification

|

SJN-500

|

SJN-1000

|

SJN-2000

|

SJN-3000

|

|

|

Evaporation ( Kg/h )

|

500

|

1000

|

2000

|

3000

|

|

|

Steam consumption ( Kg/h )

|

≤250

|

≤500

|

≤100

|

≤1500

|

|

|

Outline dimension

(Length * width * height) ( m ) |

4x1.5x33

|

5x1.6x3.5

|

6x1.6x37

|

6.5x1.7x43

|

|

|

Recycling water consumption ( L/h )

|

6

|

12

|

15

|

18

|

|

|

Evaporation

temperature |

One-effect

|

80-90

|

Mpa

Vacuum degree |

One-effect

|

0.02-0.04

|

|

Double-effect

|

55-70

|

Double-effect

|

0.05-0.06

|

||

|

Steam pressure (MPa)

|

<0.25

|

Relative density

|

1.2-13

|

||

|

Container class

|

First type (Single-effect heater)

|

||||

|

|

|

|

|

|

|

|